MIRROR MATCHING PARTS & LOWERING PARTS RETURNS are very important to high profitability.

Mirror Matching Parts: When the parts arrive at our shop for a vehicle that has been fully Blueprinted, they must have a thorough check-in process the day of arrival!! Not two days later or you will just slow the car down if any mistakes are found with missing or wrong parts. We have spent a lot of time refining this and have a pretty good system that works for us.

Here is our system:

1. RECEIVE PARTS FROM VENDOR, SCAN INVOICES INTO RO ATTATCHMENTS OR RETRIEVE FROM GRAY FILE RACK IF PARTS ARRIVED WHEN PARTS PERSON WASN’T PRESENT & RECEVE PARTS IN RO, UPDATE ANY PRICING CHANGES AND CREATE CORE CREDITS RETURN SLIPS NOW.

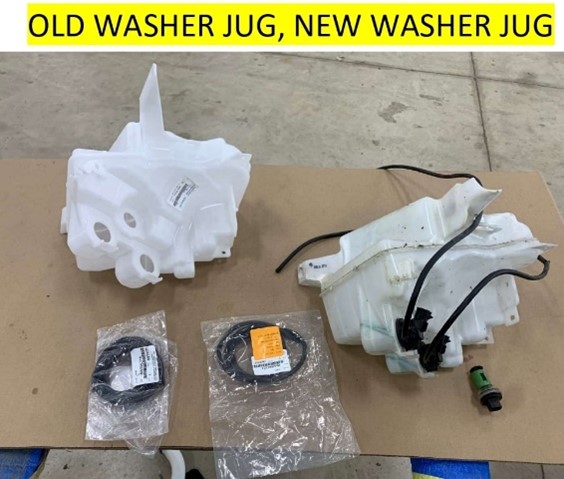

2. MIRROR MATCH ALL NEW PARTS TO OLD PARTS, THAT MEANS LAY SIDE BY SIDE AND FLIP OVER TO CONFIRM CORRECT PART.

3. REMOVE ALL NEW PARTS STICKERS AFTER PART CONFIRMATION.

4. REMOVE ALL HARDWARE, BULBS, MODULES, BRACKETS, CLIPS & Etc., FROM OLD PARTS AND INSTALL ON NEW PARTS.

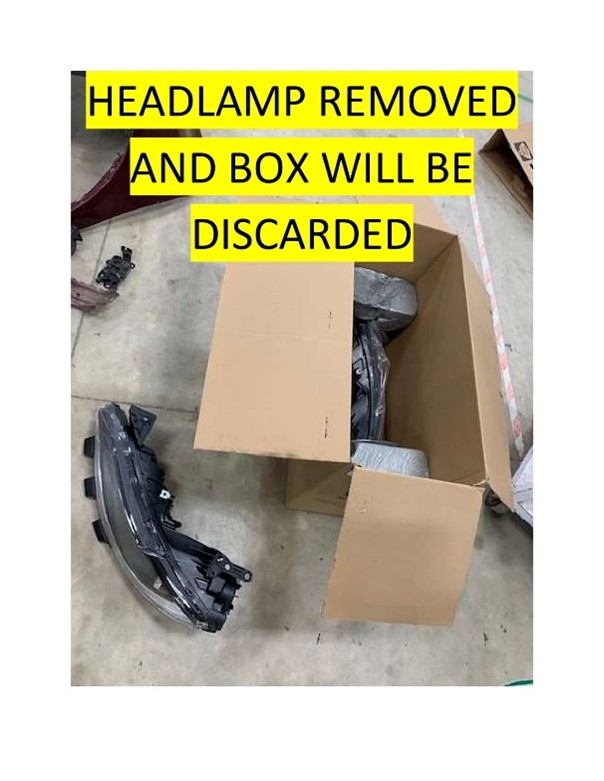

5. REMOVE ALL DAMAGED PARTS WHEN NEW ONES ARRIVE AND DISPOSE.

6. RE-BOX ALL CORES AND ATTATCH PRE-PRINTED CREDIT RETURNS.

7. DISPOSE OF ALL NON-CORE BOXES AND ANY PACKAGING.

8. SEAM SEAL ALL NEW PANELS, IF APPLICABLE AND PHOTOGRAPH FOR RO (includes doors and confirm if seam sealer is or is not on both sides of hatch gates).

9. BUILD ALL ASSEMMBLIES (headlamps, grilles, truck bumpers, running boards, windshield washer tanks Etc.) AND PLUGIN NEW HEADLAMP/TAILAMPS TO CONFIRM THEY WORK!

10. PRE-BUILT TRUCK BUMPER ASSEMBLIES MUST BE TAGGED AND MOVED TO BUMPER RACK.

11. INSTALL ALL SEATBELTS AND INTERIOR SRS COMPONENTS. INSTALL ANY ASSEMBLY WHEN THE VEHICLE DOESN’T REQUIRE BODY OR PAINT WORK IN THAT AREA. EXAMPLES: INSTALL ALL COOLING (INCLUDES VACUUM FILLING ANTIFREEZE AND CHARGING AC SYSTEMS), PLASTIC RADIATOR SUPPORTS, WINDSHIELD WASHER TANKS, ELECTRIC AIR SHUTTERS, AIR DAMS Etc. BLUEPRINT, BUILD OR BODY TECH WILL DO THIS PART.

12. MOVE CAR FORWARD TO BODY NEXT PULL.

13. PRE-CLOSE JOB.

This is our process. Our state does not require us to keep old parts. We photo any wiring harness routings or emblem locations into the RO, during BP that could be needed in the build process. Otherwise, there is not one good reason to keep the old parts, not one. So, slaughter those sacred cows’ friends!! We even cutoff bumper ends for the painters for test panels for color match, when not painting fenders or quarters.

When Mirror Matching is done, the new parts are put on R&I cart and this cart then follows the car thru the process. Some shops struggle with space and keeping the old parts along with the boxes, just multiplies the problem. Our entire shop is clock hour with a global bonus program. Therefore, we have no flat rate subcontractors who are just concerned about making a paycheck. Anything that can be done up stream to speed up the build process at the end, MUST be done. Why? If we find a problem in Mirror Matching, we have just prevented the money printing conveyor belt from stopping printing $ during the build process at the end.

I have over 5 employees in my shop that are trained to Mirror Match parts, after the invoices are received by the backend estimators. ‘Whats gonna work, TEEEEAMWORK!!’

Now, to Parts Return Ratio:

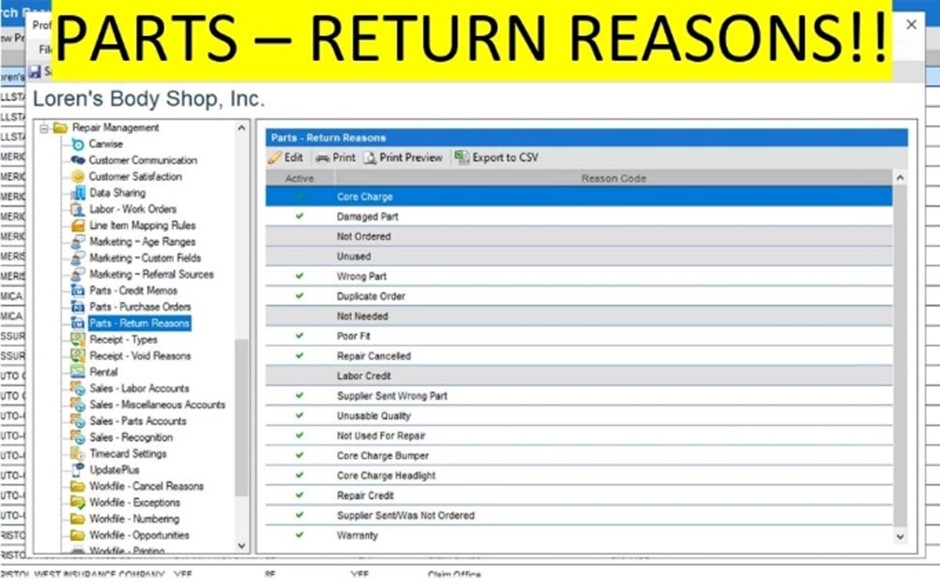

There is a very good metric, that we VERY RARELY hear anything about in collision repair KPI’s. This metric is what percentage of the parts do you order, must be returned?? A good benchmark is no more than 5% returns in dollars of those purchased, EXCLUDING CORES of course. I know we are in crazy times trying to get parts from multiple dealers Etc., but don’t use that as an excuse. ‘

Parts Return Ratio, is very good bellwether to a shops high or low profitability. If your shop’s part returns are above 8-9%, that is a red flag that entire system needs an overhaul. The problem could lie in ordering parts off an insurer’s parking lot estimate & front-end estimators just winging it & the Blueprint Dep. not reading OEM diagrams. Most shops have no clue, as to the cost in time of each returned part. Make sure your management systems are setup for the different Part -Return Reasons, so you can track this and exclude cores.

From the time a wrong part is found, the new correct one is re-ordered/arrives and then finally the credit is reconciled on the statement, EACH returned part will cost a minimum of 30 minutes to all involved parties in our shops. If you don’t believe me, go to a whiteboard with your parts people & accounting Dep., then map the time it takes for each step. I understand we get damaged parts & wrong parts sent by vendors Etc. Trouble is that most of the returns are our fault.

If a car is a borderline total in the parking lot, you better not order any parts!!! If we have just 3 returned parts per day, that’s 90 minutes or 1.5 hours per day that have been total waste by our people. We have 21 working days in the average month. 21 days X 1.5 hours = 31.5 hours PER MONTH that were wasted with parts returns or 378 hours wasted per year!! This isn’t a third of it, wrong parts mean the car likely can’t be put into production and idle inventory is soooo expensive.

Homework, go into your management system and find out for your shop what your parts return ratio is? 5% or less (excluding cores) is the goal. Above 5%, time to sit down with estimators and parts folks for a constructive problem-solving discussion!! Steve Trapp from Axalta years back made a statement I will never forget, “Just start tracking how many OEM invoices you have per RO!”