Now on to Parts, Paint & Sublet COGS. I won’t get into parts discounts very deeply here, but finding good parts suppliers, with good discounts, inventory and SERVICE is key.

This is year 2022 and if you are ordering parts by phone, fax or email, you will likely never achieve high profitability. One more thing to quickly touch on, if you repair more parts rather than you replace, this also drives down PPS as a % of sales. In the end, do the right thing for the car.

Next, please pay attention here. We have a customer’s truck in our shop right now, who paid us an additional $300 out of pocket for new OEM over A/M parts on 2014 Chevy truck. All we had to do was ask, as we were already price matching new OEM. At the end of the day great parts discounts are nice, but if the vendor has terrible service and if you’re not sure what lie they told who? The big discount isn’t worth it.

As far as driving down Paint & Materials COGS, as a % of sales.

There are MANY factors to paint profitability and I will give you just some of them.

1. Writing good estimates with good refinish labor. Here are a few things in Ex: CCC refinish times that are NOT included: Matte finish, 2nd color setup, color tint, stone guard, masking for stone guard, let down panel for three stage, 2nd car cover for priming, back tape WS & back glass, mask jambs, FPB, raw bumper prep, mask strikers-hinges-labels-door openings-hatch openings-engine compartments, inside refinish for bedsides-roofs-floors-steel-bumpers-quarter panls, weld burn damage on each adjacent panels (this is a huge one and don’t forget repair of the panels), denib/buff & Etc. If replacing door skins, add not only for edging, but inside refinish /plus R&I all components. FYI: We haven’t replaced a door skin in years, shells only. For the OEM’s to even service door skins or example truck frame sections, is just wrong. Sorry, but I don’t believe for one second they are on our side when you follow the $. Study DEGWEB.org, as they have some great videos on adding clear coat Etc.!

2. Using paint & materials calculators CAN be very helpful. Just remember, don’t EVER let paint invoicing systems be a band-aid or a crutch for poorly written estimates!! We use Axaltas Colornet. FYI: You can have Colornet setup to send you an email, if the painter goes over your set threshold for each RO.

3. Paint supplier discounts, just to touch on this one. For the most part, it comes down to how many shops you own and the amount of paint you by monthly. If you can’t get anywhere with your local supplier for a better discount, just start talking to other paint manufactures about switching lines. Then let your current supplier know, as that will stir the bucket. Talking with other non-competition shops, will give you an idea if you are being treated fairly. At the end of the day, I want my supplier to make a fair profit, provide me with good service along with good inventories and a fair discount. FYI: We order paint & supplies ONLY once per week. I don’t need drivers coming in every day chit chatting and us messing with all those invoices. FYI: The paint vendors don’t want to come in every day either, by the way!!

4. Painters mixing and usage. Axalta is telling us; we should strive for 2 ounces of water base basecoat for every refinish hour on an estimate. Solvent is 2.5 ounces. If your shop CANNOT achieve this on average, its either the painter has a very heavy finger, or the estimates are very poorly written with less than 10 average refinish hours per RO, or both are a problem.

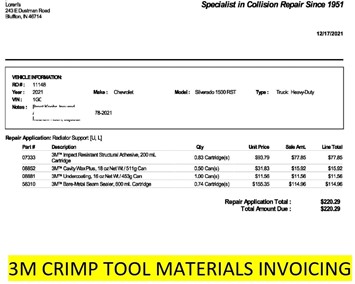

5. Leave out glues/adhesives, doubled sided tapes, seam sealers, sound deadeners, stripe tapes etc. under P&M COGS. Otherwise, these costs are supposed to be under Stock Parts in your P&L. These items are parts and NOT P&M. So many shops don’t bill for these parts and blame paint manufactures for high paint costs. If you are not familiar with 3M’s CRIMP tool for invoicing for these items, please contact your local 3M rep and use this great tool (see photo of one of my invoices).

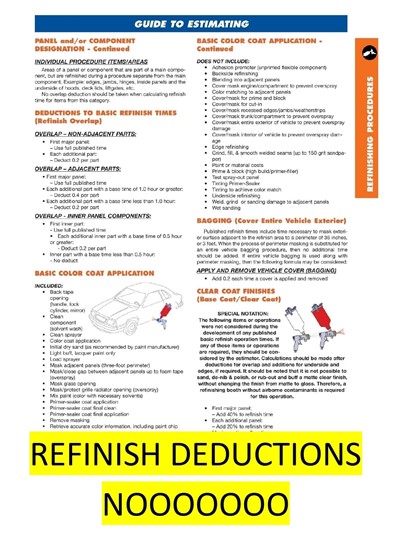

6. Don’t accept refinish reductions on repaired panel. We may accept -.1 or -.2 deduction, but that its!! There are 17 operations in the CCC’s p-page G35 BASE COAT COLOR APPLICATION (see photo). Remember, application of the actual basecoat is only one of the operations!! Put your foot down or some insurers WILL steal from you if YOU let them, it’s just that simple. If the insurer can rob you of just one refinish hour off your estimate, they have just taken approx. $100 out of your billfold!

7. Paint CAPS are illegal in most states. Now some communist insurers have changed the wording to, ‘Thresholds’. You must keep a close eye on these in Estimate Rules (In CCC) IF you download insurers estimates. If they CAP you, then back to invoicing them!! At the end of the day, in your P&L you should strive for Paint & Materials SALES to be at least 10% or above of your Gross Sales and Paint & Materials COGS at 5% or below of your Gross Sales or 50% GP. As far as sublet GP. You can work out a deal with your vendors, for early pay discount and add markup in the estimate. About 90% of the time, we are paid a labor time for dropoff and pickup for sublet time. Two people, two cars and gas for both vehicles.