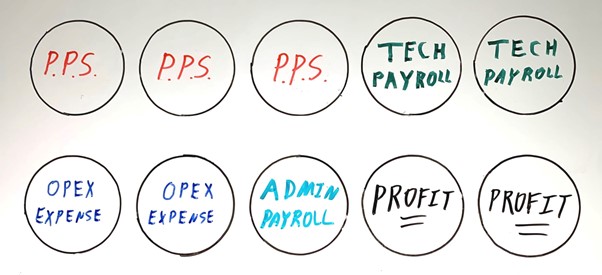

Hopefully you took some time and did an analysis of your shop using the 10 dimes exercise.

If you didn’t do the exercise and you already have a near 20% net profit, I understand. If you didn’t do the exercise and you have say a 5,10 or even a 15% net profit, read these two quotes from two great men of the past.

“Being average means, you are as close to the bottom as you are the top”, John Wooden.

“Leadership is the challenge to be something more than average”, Jim Rohn.

So, if you have a high Paint, Parts & Sublet COGS% of Gross Sales at say 38% or above, that’s a problem. We all have those months with certain wrecks that have extremely expensive parts. Then we have other months with a lot more repair vs replace and low parts GP. I would look at your PPS COGS % in a minimum of 3–6-month average in your P&L. If all your work is high end cars, your PPS COGS % will run higher than most shops. So, the easiest way to lower this cost % and raise your net profit is plain & simple. We must write better estimates/repair plans after Blueprint! I have seen estimates from many shops that are missing 5-10 hours of work done not billed for labour on average.

A great coach I had almost 15 years ago now, told me something I will never forget. He said, “Greg, if you’re not getting denied stuff on your estimates, you’re not asking for enough!”

If you don’t know what your average estimate hours are for repairs you have completed, how will you ever know what needs to be fixed?? When you figure this out, make a graph with each of the last six months average RO hours per repair order. Start tracking this monthly going forward to improve the trend!! If you have a management system, this should be easy. Be sure and leave out total losses and selfpays. The days of having 22-24 average labour hours per RO are long in the past now. The only exception to this is, if you are in some type of DRP agreement that your shop only gets light hits. The vehicles of today are so much more complex, than cars built from say 2000-2010 and the complexity is multiplying now of course.

A starting point to better estimating is understanding the breakdown of the estimate required and making sure that you review every forgetables list that you have. Greg refers here to what takes place for him by studying the various industry platforms to maximise his knowledge. Examples for Greg are CCC, Audatex and Mitchell’s P-pages. (See the Degweb link below). Go to the link below and view each estimating software’s P-pages in the Estimate Toolbox. CCC PDF 2021 Version is about 40 pages, Audatex DBRM is 188 pages and Mitchells is kind of communist to try and print. It’s doable but will take probably 30 minutes to download each segment to print. Anyway, print them all out, punch holes in them & put them in a big three ring binder. Take them home and start studying them.

For shop owners unwilling to take the time to do this, they will have to be content working very hard for very little. It’s just that simple folks! We just can’t think we can click our way thru the estimating software and cross our fingers we will make a nice net profit. In the coming days we will work towards ways to write more thorough estimates, but we must set the stage to have a system in place to make this possible!!