Planning Plus Software was recently installed to Liquid Metal Marine in Canada. Planning Plus Director, Gavin McGahey talks with Robyn about how it all came about and their experience so far.

Gavin

Welcome to Planning Plus, Robyn from Liquid Metal Marine. Robyn, could you just tell us a little bit about the business? Where are you located & what does the business produce?

Robyn

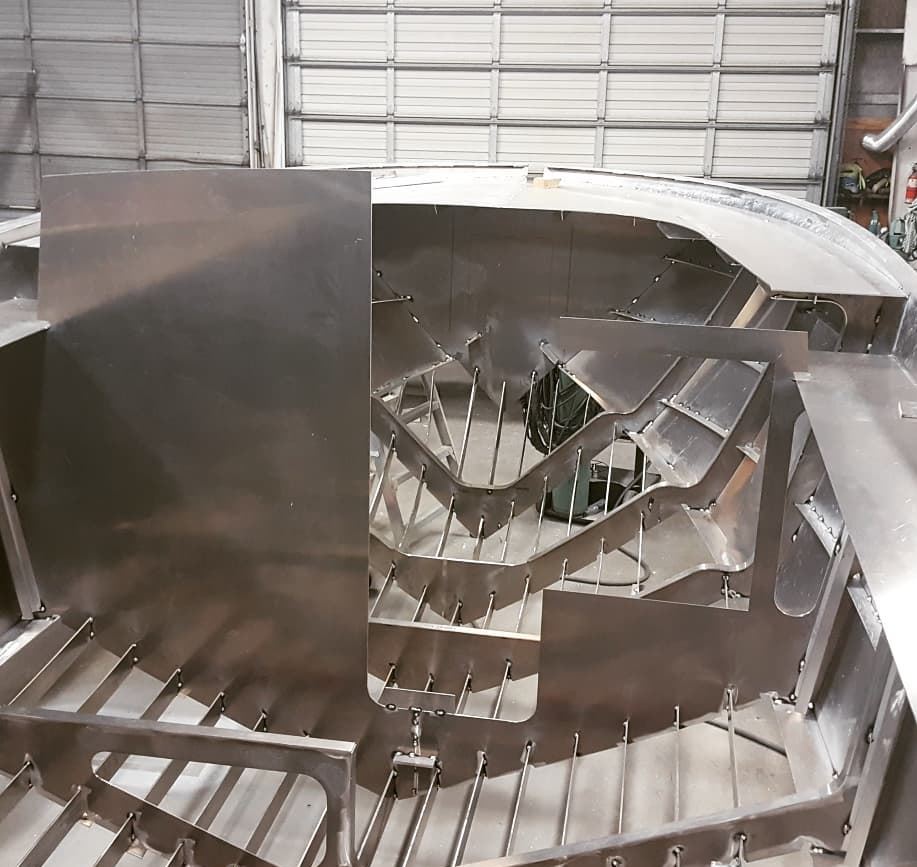

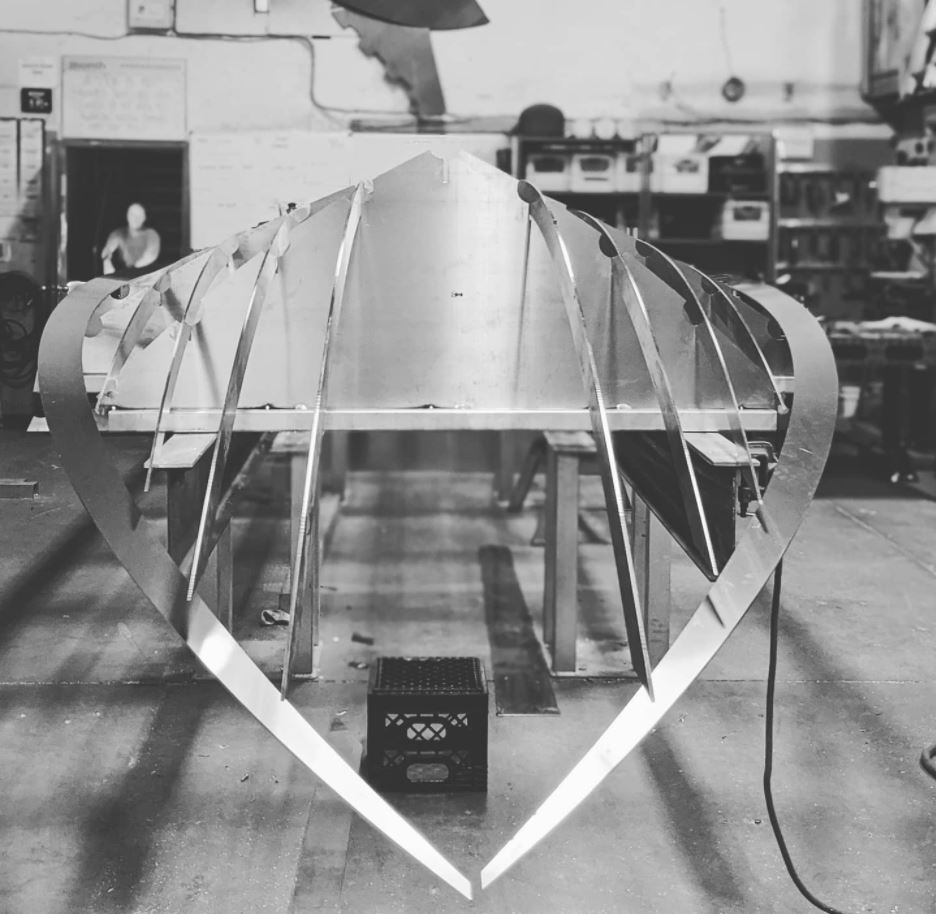

Liquid Metal Marine are an aluminum boat builder located in Sydney, BC in Canada. We have been in business since 2000 and we build a variety of boats for pleasure and government use. Usually, the mix is kind of around 50/50 and ranging in sizes from a small 12-foot boat to the biggest one being a 65-foot catamaran which took up the whole shop.

Gavin

How many technicians do you employ there?

Robyn

Usually between six and ten.

Gavin

Can you describe what was happening in the business that triggered you to look for a better way of doing things?

Robyn

We have a lot of large projects that take months and months to build and we would get small jobs coming in from regular customers who we do not want to turn away or people with emergencies. So, we would fit them in, and that job might only be a half a day job, or a week and it seemed like it would not affect the schedule, but we really needed something to show us how much it would affect the deadline of the overall project that we were pushing off.

Gavin

What was the feeling like in the business when you did not have control of where your workflow was?

It was time to take control of their workflow

Robyn

Stressful. Definitely. Especially when you get closer to the end of a project and you realize, we are not where we need to be. We did not have anything to show the guys on the shop floor what they needed to be reaching for day in, day out. They would see the project as, “I’m coming to work today and working on this.” They had no real urgency of deadlines. We would be approaching a deadline & realizing how far behind we are, they did not understand the stress this created for the office because it is just a daily thing for them.

Gavin

It was sort of like, just come into work and just go about my day as I go about my day. And if someone comes out and tells me something else to do, I will just do it then and go home at the end of the day.

Robyn

Absolutely, it was hard for us to know that by fitting a smaller job in how far we were falling behind on other projects. We had no proper scheduling system to really identify our true workload.

Gavin

How did you find out about Planning Plus and what were your initial thoughts when you saw it?

Robyn

Another local company, BMT Group was using Planning Plus and we happened to just see it on one of their monitors and asked what it was. They invited me over and did a quick demo. The scheduling aspect was the big thing that we saw, especially the weighting of the employees. Being able to show that our apprentices will take twice as long as the journeyman, because the way we decide how long a job is going to be is based on journeymen hours. We really needed to see how long the job would take if our apprentices were working on it also.

Gavin

You are building Aluminum boats and you saw our software in a collision & truck repair facility. So, what was your first experience like with Planning Plus, and your first interactions with the Planning Plus Team?

Robyn

The experience was good. Planning Plus offered to make changes where you could in the system, and we gave you all the feedback on what we needed to be able to do. You were able to change small things here and there and came up with ideas of how to use your current system that would apply to what we needed to do.

Gavin

That is right, because when you think about it, it does not matter whether we’re in a collision repair shop or we are in an Aluminum boat building company, we are selling labor and we are then breaking that labor down into, blocks of time. We are then planning those blocks of time against the technicians and we are also looking at that block of time against the technician’s return on investment.

Robyn

Scheduling was the big thing that we were looking for and that is what Planning Plus does well.

Gavin

It is quite interesting creating the tasks and sub-tasks for your business. We started with a blank canvas and worked out what are the tasks that are applicable for an aluminum boat to be built? We then broke those tasks down. Some of the tasks from my recollection, we created tasks like fabrication and electrical and hydraulics, and still had painting and other common tasks, but we just looked inside your four walls to work out what are the common things that you do and then built the database to suit that.

Robyn

The great thing is that we can constantly modify that. I think we started with a fabrication and welding task, and then we determined that it is better to just have that as one task because generally if you are going to fabricate something, it is usually going to have some welding component to it.

Gavin

You ran Planning Plus in the office for the first month or so maybe even a little bit longer so you could get a deeper understanding of what would best suit the workshop. What was your experience of running the system in the office first? What were the benefits that you could see that it was going to bring once you engaged the production staff?

Robyn

It was good to be able to go through and try things and set up different tasks or flags and then do mock jobs and fill them all in and see if that will work. We wanted to do this before we were to send it out to the shop so that they were not testing it with us and then they did not have to learn and relearn different things. From my side of things, just being able to put all those overall hours in for all the jobs we knew we had was able to show us how many months out we have work planned for. This assisted us to gain a reality when bidding on future projects as well.

Gavin

So, you could then basically see in advance once you planned those tasks up where you had opportunities to either fit more work in or if the schedule did not allow this you could then review adding another Technician to the team.

Robyn

Yes, it was an eye opener on one or two when we realized, wow, that is going to take a bit longer than we thought.

Gavin

Did you see this as a major benefit of having a visual display?

Robyn

Yes, before that, it was pen and paper and just trying to draw down numbers and figure it out that way.

Gavin

When you introduced it to the production team, we put a computer out in the workshop floor, along with the TV, how did they interact? How was the buy-in?

How did the Production team react to the new system?

Robyn

Mixed reaction at first, a couple of them thought it was great because they are going from pen and paper, writing out all their details for the day and now they can just select what tasks they are on and they are away. However, a couple did not really see the benefit to it and felt they were wasting time standing at the computer? It was a mixed bag, they are slowly getting the hang of it and appreciating it more and more.

Gavin

It is all about engaging the whole team, from the office to production and back, they can send a message to you. You can send a message to them. We can keep them engaged with the job as opposed to possibly the old process of it is what it is with no urgency.

Robyn

The biggest thing is we want them to understand that what they are working on, is not just a small component, it is part of this overall project and it has all got to come together in certain timeframes to make this whole project go out.

Gavin

What have you found to be the major benefits now that you are over four months in? Have the guys settled down? I also noticed that you are using our eForms as well. So, what type of benefits does that bring?

Robyn

I think we are still working towards the major benefits that we will get out of it. I think that, once we are confident and everybody in the shop can use it more efficiently, that it will help with our scheduling and keeping things on task and knowing when they come into work, what they are working on that day. Whereas they used to have to stand around wondering what they had to do. The eforms has made a huge difference because before it was a binder full of paper and they would have to search through it for certain jobs. Now they are attached to all the jobs and I can send them a quick message out to the shop if needed if I know that something coming up, I can remind them to use an eform & that has made a huge difference.

Gavin

Are you glad that you made the purchase?

Robyn

Yes, we are. Of course, everybody wants things to be great now. Kristy, the business owner & I can see the benefits are growing and we are focused on learning and adapting the system and getting everyone to use the system as it is intended.

Gavin

Yes, and that comes through how we drive the system. How committed are we to make the changes? How committed are we to approach and coach the team and make sure they understand the system? If we are continually behind the eight ball, that builds frustration and builds more stresses, and no one likes to be working from that state of mind.

Robyn

That is right, it is no fun to be stressed, but I think they are smart and as I said, we are, or I’m trying to do more one-on-one demos with them every day, even though it might get a bit of annoying to them or like, remember to do this, remember to do that. I think in time it will become second nature and things will be that much better.

Gavin

It is just driving repetition. I remember you told me a little while ago that you trained one of the guys, you showed him something one day and then you looked out into the workshop and saw that he was then showing someone else how to do something within a couple of hours of what you just showed him. That would have been a good feeling to know that it is being acknowledged and shared.

Robyn

Yes, it was. We had had our little five-minute lesson that day with that employee. And yeah, later in the day somebody was asking, I think, how to split a task or something. And he was like, Oh, well you just do this. And I was like, look at you go, it is easy, you have just got to remember how to do it. Once you keep doing it, it will be easy. I think they are starting to see the benefit and it is just repetition and getting used to it.

Gavin

Awesome. What does the future look like for Liquid Metal Marine?

Let’s fill up the Planner!

Robyn

Filling up the planner. People keep asking for more work and we can tell them that according to our new scheduling system, you are a few months out. Also hearing from Jenny about all the new stuff that is coming with the cloud-based version, I think that will do so much more for us as well.

Gavin

That is great, thanks for your time today. It has been awesome to talk to you. You are way over there on the other side of the world & it is coming to the end of your day and it is just the start of our day for us.

Robyn

Coming to us from the future right now, right?

Gavin

Yes, we are coming to you from the future. We are always one day ahead in Australia and we like to be like that, one day ahead of the world. You are also winding down the end of your Canadian winter?

Robyn

Where we are on Vancouver Island, we do not get much of a Winter. I think we had four days of snow this year which is not a lot, we get cool temperatures and a lot of rain.

Gavin

That is awesome, Robyn. Thank you very much for that. We really appreciate your feedback.

If you would like to see if our Bodyshop Software is right for your business, book in for a free demo today.

https://calendly.com/gavinpp/planning-plus-software-demonstration